We will discover that the majority of them are affected by the activities of the laser system after we narrow down our focus to grasp how it is manufactured. Laser applications are as diverse as our imaginations may take them. We can start with industrial applications like cutting and welding, then move on to the medical industry for scanning and precision tool manufacturing, then on to the luxury industry for finishing and imprinting, and finally, to any industry, we can think of in the end. So, what exactly is laser-based technology?

The laser principles include

Lasers are defined as follows: “A laser is a device that creates light via a process of optical amplification based on the stimulated emission of electromagnetic radiation,” according to the definition. Contrary to popular belief, the word LASER is an abbreviation for “light amplification by stimulated emission of radiation,” which stands for “light amplification by stimulated emission of radiation.” While the laser has extended over a broad range of uses, as stated above, its origins are still not that far away from the present. When Theodore H. Maiman was working at Hughes Research Laboratories in 1960, he created the world’s first laser.

While the phrase LASER seems to be a benign statement, it is an abbreviation for “light amplification by stimulated emission of radiation,” according to the National Institute of Standards and Technology.

Work With the Laser

When it comes to lasers, there are five major components, which are as follows: gain medium, laser pumping energy, a high reflector, an output coupler, and a laser beam. A gain medium is a substance that has a strong propensity to magnify light that has been stimulated to emit more light. When the light of a given wavelength travels through a gain medium, the strength of the light is amplified (increased).

TEPROSA’s manufacturing processes and materials

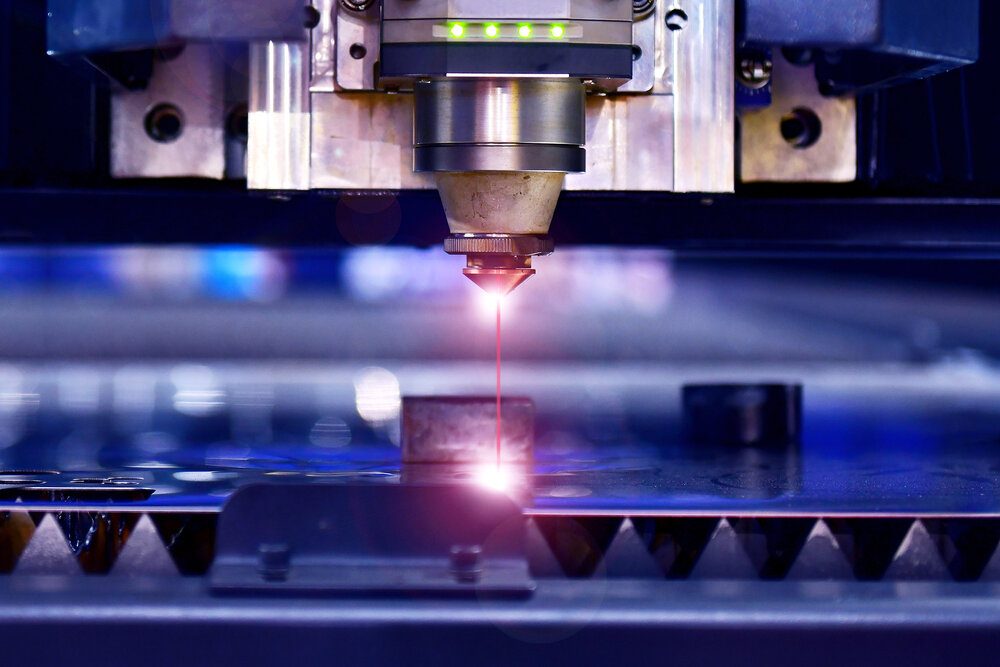

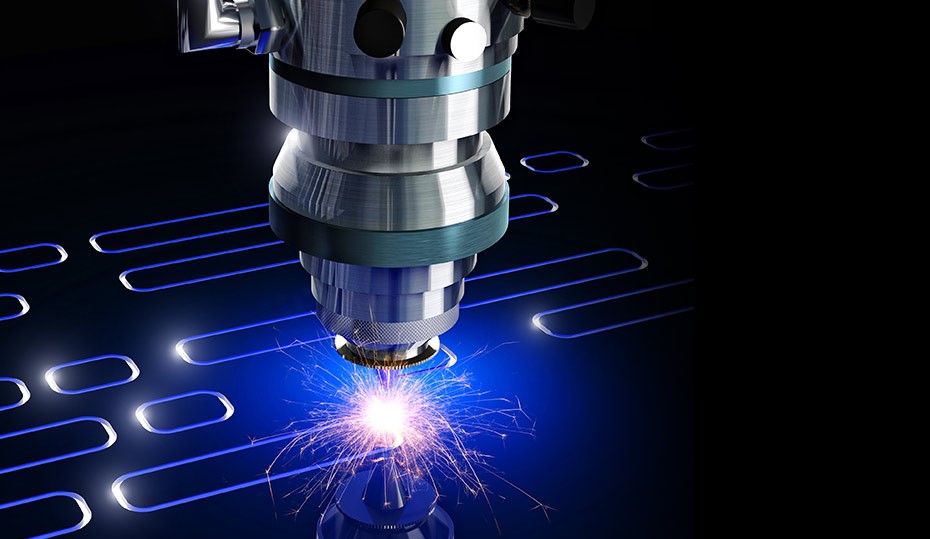

According to the TEPROSA, when using fibre lasers for laser cutting, three basic processes must be followed. Even though all three processes use laser radiation as their cutting principle, the underlying principle of all three processes is the same: in all three processes, a highly focused laser beam is bundled together with the appropriate beam guide and the processing head (focusing optics) before being directed onto the workpiece to be processed. The resultant fumes and melt are subsequently evacuated by the use of a procedure gas.

Pumping is the mechanism by which energy is provided to the gain medium for it to magnify light while a laser is in operation. The energy supplied is in the form of an electric current or light with a variable wavelength, depending on the application. Pump illumination is provided by another laser or flash lamp.

A typical laser receives feedback via a pair of mirrors that are positioned on each side of the gain medium; this arrangement is referred to as an optical cavity in certain circles. Light bounces between these two mediums many times before passing through a gain medium and being amplified each time along the process. One of the two mirrors that serve as an output coupler is transparent, allowing some light to pass through it. The other mirror serves as an input coupler and is opaque. The form of the mirrors is determined by the design cavity (flat or curved). The form of the mirrors determines the type of light, which may be either divergent or narrow beams in nature. The term “Laser Oscillator” refers to this kind of amplification equipment.

As a consequence of its capacity to concentrate power with precision, customise laser sources to accomplish broad laser applications, and operate at a quicker pace than other technologies, the laser has gained widespread acceptance in a variety of fields since its invention.